|  |

Remarks on serrated gratings

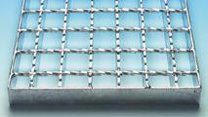

| XSP type No.1 |  |

|

|  |

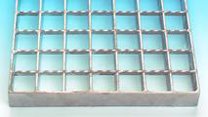

| XP type No.2 |  |

|

|  |

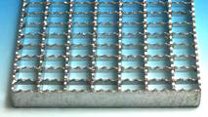

| XP type No.22 |  |

|

|  |

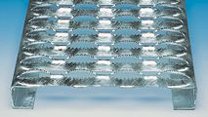

| XP type No.3/31 |  |

|

|  |

| XP type No.32 |  |

|

|  |

| XP type No.42 |  |

|

|  |

| BP type BZ |  |

|

|  |

| BP type BP-Ü |  |

|

|  |

| BP type BN-O |  |

|

|

Metal gratings having members without serrated walking surfaces, generally have sufficient slip resistant properties for normal use in good environmental conditions. However, in locations where dirt, oil, grease, water or food increases the risk of slipping, there is the requirement for an improved slip resistant walking surface on floor coverings. This can be achieved by supplying either metal gratings with a series of notches or serrations in the top surfaces of bearing bars and/or cross bars or perforated metal planks having a series of raised pattern punched holes in the top surface.

In order to meet the different levels of slip resistance several types of serrated top surfaces have been developed and are described as follows.

•SP Serration no. 1 and 11;

•P Serration No. 2, 22, 3, 31, 32 and 42;

•B Serrated qualities because of surface specifications

The Occupational Safety Authorities have determined criteria relating to serration. Instruction sheet BGR refers to:

• working locations with an increased danger of

skidding,

• the inspection procedure to find criteria for serration

and

• the categories of the inspected floor coverings.

|

|